Trapezoidal sheets

Trapezoidal sheet steel

Trapezoidal sheet - use as roof and wall panel

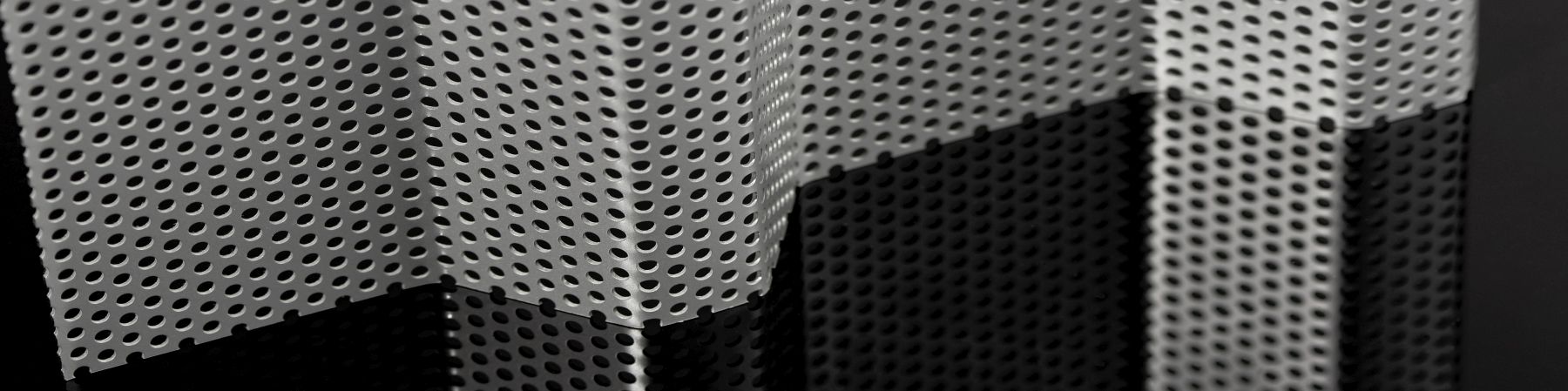

Trapezoidal sheets are often applied for industrial building. The load carrying system is often built of steel. The trapezoidal sheets are applied for different components such as roof covering, wall covering or ceiling lining.

The applicable DIN 18 807 provides general guidelines for the application of trapezoidal profiles such as minimum limit, tolerance indication, corrosion protection and the calculated notation of section and measurement properties. The light component elements possess top and bottom flanges as well as bars. To improve the load bearing behaviour the flanges or belts sometimes have beadings in longitudinal as well as in transverse direction which are named, depending on the type of moulding, corrugation, groove or displacement.

Trapezoidal sheet - advantagesDue to their light weight the trapezoidal sheets are easy to handle. The special construction of the layed on edge sheets allows an augmentation of the bearing load. The easy mounting and the rapid construction progress are in favour of trapezoidal sheets as construction material.

Trapezoidal sheet - warm and cold roof

Utilized as a roof sheet the trapezoidal sheet steel settled in positive direction, when the wide belt is fixed outward or rather at the head and the small belt at the bottom. This system of laying is used to assemble a warm roof, that means that it serves as base for another roof system. If you would like to use the trapezoidal sheet steel as a cold roof, the sheet is settled in negative direction. The small belt is fixed outward or rather at the head (to the weather side) and the wide belt at the bottom. This laying system is used to avoid the joint of mounting widths laying in the channel flow.

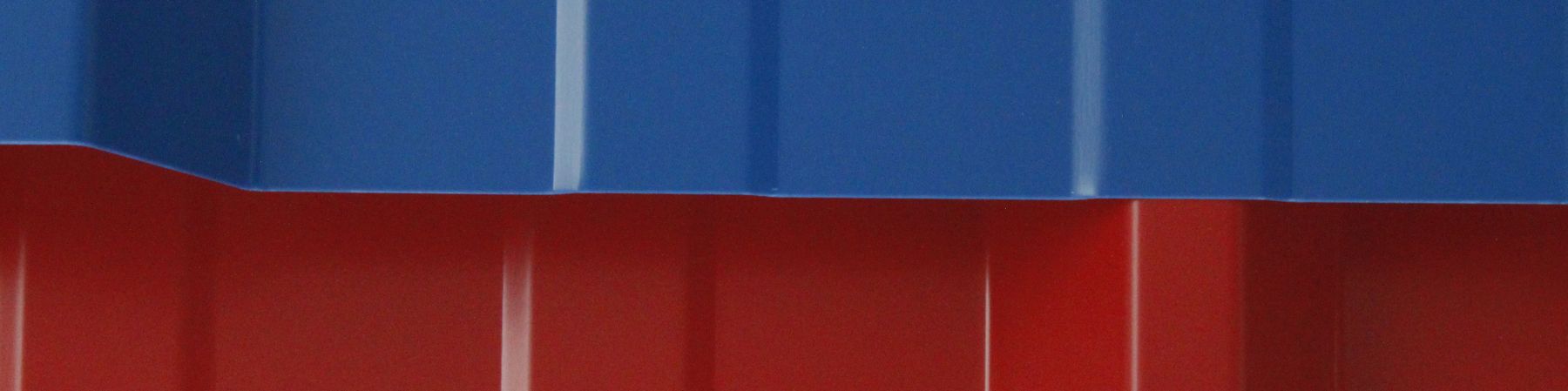

Trapezoidal sheet - coatings

Trapezoidal sheets steel are available in different designs such as coil galvanized, aluzinc and coil galvanized with plastic coating in the layout DU, Polyester, PVDF, Plastisol = HPS 200, Armatec, Armatone with condensation-inhibiting foil or sound absorption coating (as well as geomembrane) available.

Trapezoidal profile - measurements - technical data

For optimizing the necessary trapezoidal sheets according to the static requirements the of tables of applied load are helpful. One distinguishes between single-span beam, two-span beam and three-span beam. Regarding to the span width and the extra load the appropriate profile with the thickness of sheet can be found in the tables of applied loads. Using the tables of applied loads is only a pre-measurement which does not replace a structural analysis of statics.

Trapezoidal sheets made of aluminium

Trapezoidal sheet - use as roof and wall planel

Trapezoidal sheets are often applied for industrial building. The load carrying system is often built of steel or wood. The trapezoidal sheets are applied for different components such as roof covering, wall covering or ceiling lining.

The DIN 18 807 provides general guidelines for the application of trapezoidal profiles such as minimum limit, tolerance indication, corrosion protection and the calculated notation of section and mesurement properties. The light component elements possess top and bottom flanges as well as bars. To improve the load bearing behaviour the flanges or belts sometimes have beadings in longitudinal as well as in transverse direction which are named, depending on the type of moulding, as corrugation, groove or displacement.

Trapezoidal sheet - advantages

Due to their light proper weight the trapezoidal sheets are easy to handle. The special construction of the layed on edge sheets allow an augementation of the bearing load. The easy mounting and the rapid construction progress speak in the favour of trapezoidal sheets as construction material.

Trapezoidal sheet - cold roof

As roof sheet the trapezoidal sheet made of aluminium lays in positive direction, if the small belt is outward or rather on the top and the wide belt is fixed on the bottom. This system of laying is used for assembly of a cold roof.

Trapezoidal sheet - designs and coatings

Trapezoidal sheets made of aluminium in design alu blanc, alustucco, alu plane. As layouts plastic coatings in Polyester, PVDF with condensation-inhibitingfoil or sound absorption coating (as well as geomenbrane) available. Despite of this trapezoidal sheet made of aluminium are also deliverable in anodising quality.

Trapezoidal profiles - measurement - technical data

For optimizing the necessary trapezoidal sheets according to the static requirements the of tables of applied loads are helpful. One distinguishes between single-span beam, two-span beam and three-span beam. Having regard to the span width and the superimposed load the appropriate profile with the thickness of sheet could be found out of the tables of applied loads. Using the tables of applied loads is only a pre-measurment which does not replace a structural analysis.

Trapezoidal sheets stainless steel

Trapezoidal sheet - use as roof and wall plates

Trapezoidal sheets are often applied for industrial building. The load carrying system is often built of steel. The trapezoidal sheets are applied for different components such as roof covering, wall covering or ceiling lining.

The applicable DIN 18 807 provides general guidelines for the application of trapezoidal profiles such as minimum limit, tolerance indication, corrosion protection and the calculated notation of section and measurement properties. The light component elements possess top and bottom flanges as well as bars. To improve the load bearing behaviour the flanges or belts sometimes have beadings in longitudinal as well as in transverse direction which are named, depending on the type of moulding, as corrugation, groove or displacement.

Trapezoidal sheet - advantages

Due to the light weight the trapezoidal sheets are easy to handle. The special construction of the layed on edge sheets allow an augmentation of the bearing load. The easy mounting and the rapid construction progress are in favour of trapezoidal sheets as a construction material. Trapezoidal sheets stainless steel are often used in food industry, in chemical industry or for offshore wind energy plants at sea. The stainless steel is deliverable in general in qualities 1.4301. 1.4401 (both only in 2B-finish) and additionally in UGIBRIGHT® in quality 1.4526. All these qualities are covered with a protection foil on both sides and comply with the European Standard EN 10088-2 and EN 10259.

Trapezoidal sheet - warm roof and cold roof

Utilized as roof sheet the trapezoidal sheet made of stainless steel laid in positive direction, when the wide belt is fixed outward or rather at the head and the small belt at the bottom. This system of laying is used to assemble a warm roof, so it serves as a base for another roof system. If you would like to use the trapezoidal sheet steel as cold roof, the sheet is laid in negative direction. The small belt is fixed outward or rather at the head (to the weather side) and the wide belt at the bottom. This laying system is used to avoid that the joint of mounting widths do not lay in the channel flow.

Trapezoidal sheet - coatings

Trapezoidal sheets stainless steel are available in different designs such as coil galvanized, aluzinc and coil galvanized with plastic coating in the layout DU, Polyester, PVDF, Plastisol = HPS 200, Armatec, Armatone with condensation-inhibiting foil or sound absorption coating (as well as geomembrane).

Trapezoidal profile - measurements - technical data

For optimizing the necessary trapezoidal sheets according to the static requirements the tables of applied load are helpful. One distinguishes between single-span beam, two-span beam and three span-beam. Regarding to the span width and the extra load the appropriate profile with the thickness of sheet can be found in the tables of applied loads. Using the tables of applied loads is only a pre-measurement which does not replace a structural analysis of statics.

Trapezoidal profile building construction- Introduction DIN 18 807

Detailed infromations regarding to available trapezoidal profiles

List of detailed informations regarding to the available trapezoidal profiles:

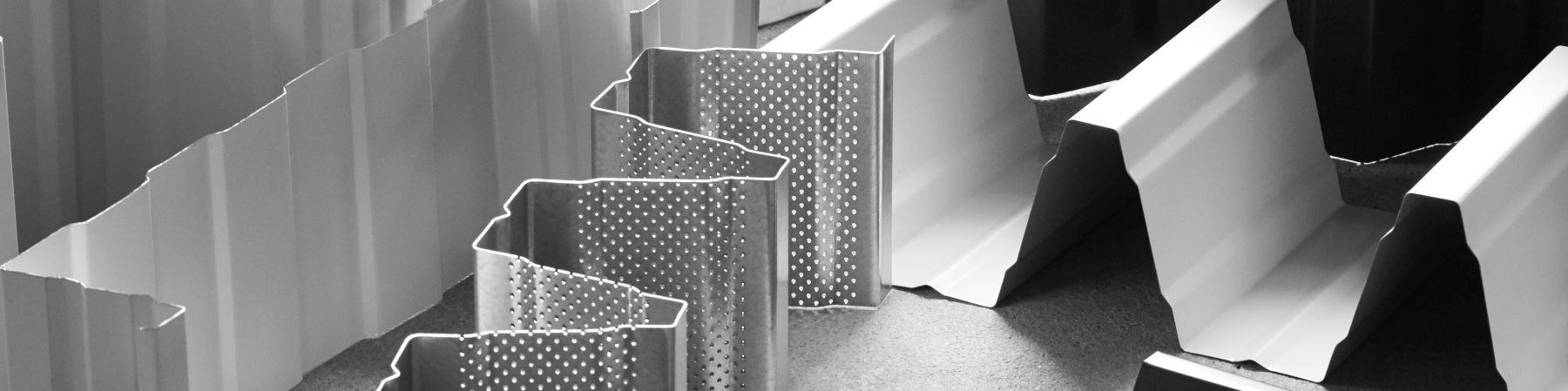

Trapezoidal sheets steel contures

Trapezoidal sheet steel available sheet lengths

Trapezoidal sheet steel available sheet thickness

Trapezoidal sheet steel table of loads

Trapezoidal sheet aluminium contures

Trapezoidal sheet aluminium available sheet lengths

Trapezoidal sheet aluminium available sheet thickness

Trapezoidal sheet aluminium load table

Trapezoidal sheet stainless steel contures

We will be pleased to provide you with individual advice based on your requirements. (contact)